Future Trends in Membrane Bioreactor Technology and Its Global Impact

Future Trends in Membrane Bioreactor Technology and Its Global Impact

Blog Article

Comprehending Membrane Bioreactors: The Future of Wastewater Therapy

Membrane layer bioreactors (MBRs) represent a noteworthy development in the area of wastewater treatment, integrating biological processes with advanced membrane purification to boost effluent high quality. As worldwide water deficiency and strict governing frameworks end up being progressively pushing issues, MBR modern technology provides an efficient action with its capacity to decrease footprint and maximize resource recovery. The adoption of MBRs is not without its challenges, which warrant careful consideration. What are the key variables influencing their implementation and long-term stability in various contexts? The solutions may reshape our strategy to wastewater administration.

What Are Membrane Layer Bioreactors?

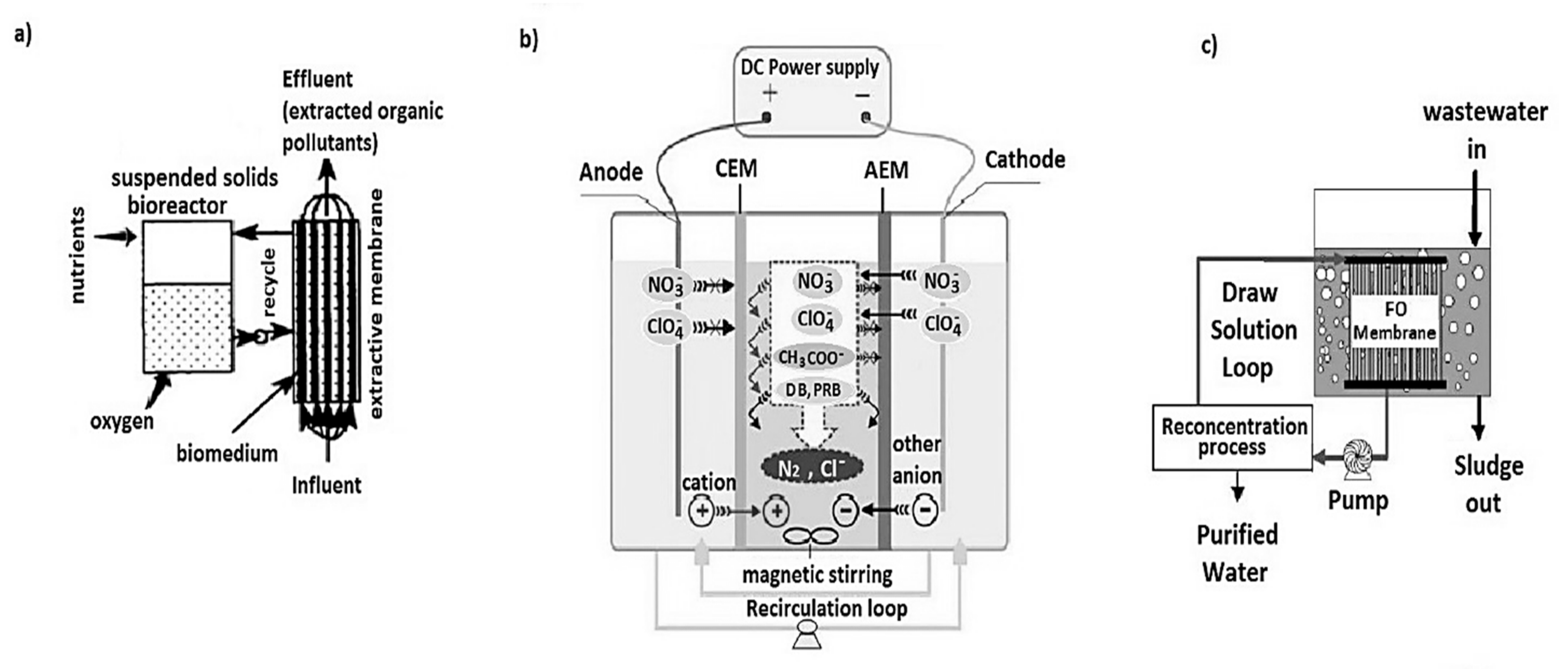

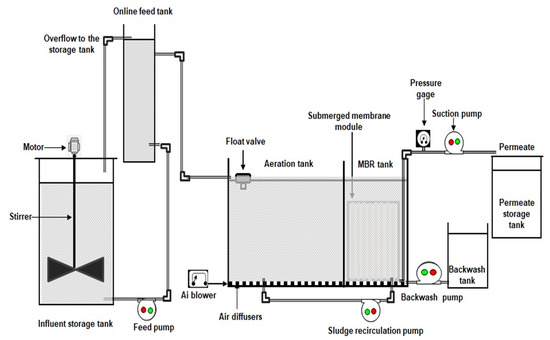

The core parts of MBR systems include a bioreactor where microbial activity takes place and a membrane layer system that filters the mixed alcohol. This double performance makes it possible for the simultaneous degradation of organic matter and solid-liquid splitting up in a solitary step. MBRs can operate in both immersed and exterior setups, with submerged systems being more common due to their portable style and operational effectiveness.

The adoption of MBR innovation has actually gained grip in various applications, varying from metropolitan wastewater therapy to industrial effluent management. MBRs are especially beneficial in scenarios where space is rigid or limited effluent high quality requirements must be met. By maintaining a high focus of bacteria within the bioreactor, MBRs boost the deterioration of natural toxins, consequently yielding greater therapy performances contrasted to traditional approaches.

Secret Advantages of MBR Modern Technology

The integration of organic treatment with membrane layer purification in MBR systems uses numerous benefits that establish it aside from typical wastewater treatment methods. Among the main advantages is the boosted effluent quality. MBRs successfully get rid of suspended microorganisms and solids, accomplishing higher levels of filtration that satisfy rigid discharge criteria and facilitate water reuse applications.

Another significant benefit is the decreased sludge production. MBR systems produce much less excess sludge, causing lower disposal prices and a decrease in ecological impact. The shut nature of the membrane system lessens the danger of smell discharges and enhances overall procedure control.

Last But Not Least, MBRs are functional and adaptable, making them ideal for numerous wastewater types, including commercial and local sources. The capability to integrate with advanced therapy modern technologies better boosts their efficiency, making MBRs an appealing option for the future of wastewater administration.

Challenges and Limitations of MBRs

While MBR technology supplies many advantages, it likewise faces numerous difficulties and constraints that can impact its widespread adoption. One substantial difficulty is the high capital and operational expenses related to MBR systems. The preliminary financial investment for membrane materials and the required facilities can be substantial, making it much less accessible for smaller sized markets or municipalities.

Additionally, membrane layer fouling stays a crucial problem that can reduce system performance and boost upkeep needs. Fouling occurs when solids, natural matter, or bacteria build up on the membrane surface area, causing lowered leaks in the structure and calling for regular cleansing or replacement.

One more restriction involves the intricacy of the innovation. MBR systems require competent personnel for procedure and maintenance, which can be an obstacle in regions with limited technological proficiency. The disposal of spent membranes provides ecological concerns, as the products are usually not eco-friendly and can add to throw away management difficulties.

Last But Not Least, while MBRs can properly treat a large range of wastewater, they might not appropriate for all applications, particularly those with high concentrations of fats, oils, and oils, requiring further research study and innovation to deal with these limitations.

Applications of Membrane Layer Bioreactors

In various sectors, membrane bioreactors (MBRs) have actually emerged as a flexible option for wastewater treatment (Membrane Bioreactor). Their applications span community, commercial, and farming settings, showcasing their versatility and performance in diverse settings. In community wastewater treatment plants, MBRs significantly enhance effluent quality, permitting water reuse and minimizing the environmental effect of discharged wastewater

Industrially, MBRs are employed in food and drink handling, fabric production, and pharmaceutical production, where they successfully treat high-strength waste streams. Their ability to manage varying and fluctuating loads impurity focus makes them specifically important in these fields. Additionally, MBRs assist in the removal of virus, suspended solids, and organic issue, adding to compliance with strict discharge laws.

In agriculture, MBRs are increasingly used for dealing with farming overflow and animals wastewater, enabling the recovery of nutrients for fertilizer manufacturing. They likewise aid in the therapy of greywater for irrigation, promoting lasting water monitoring techniques.

The flexibility of MBRs is further shown by their integration with various other technologies, such as anaerobic digestion and advanced oxidation procedures, enhancing overall efficiency and resource recovery in wastewater treatment systems.

The Future of Wastewater Therapy

Developments in innovation and a growing focus on sustainability are forming the future of wastewater therapy. Membrane layer bioreactors (MBRs) exemplify this change by integrating biological therapy procedures with membrane layer filtering, causing high-quality effluent suitable for reuse. The fad towards round economic situations is motivating facilities to embrace MBRs for their capacity to recoup sources, such as water and nutrients, from wastewater.

Innovations in membrane materials and setup are enhancing the performance and longevity of MBR systems, minimizing functional costs and energy intake. Smart innovation find out assimilation, consisting of real-time surveillance and automated control systems, is further optimizing performance and enabling anticipating upkeep, thus lessening downtime.

Furthermore, regulative stress and societal expectations are pressing municipalities and markets to take on even more lasting methods. Membrane Bioreactor. The shift in the direction of decentralized wastewater therapy remedies is gaining traction, enabling localized therapy that minimizes transportation expenses and energy use

Verdict

Membrane layer bioreactors (MBRs) stand for a transformative method to wastewater treatment, incorporating organic procedures with innovative membrane technology. The advantages of MBRs, consisting of boosted effluent high quality, minimized spatial requirements, and lower sludge manufacturing, place them as a sensible solution in the middle of growing urbanization and stricter ecological laws. Despite existing obstacles, the continued advancement in membrane materials and functional methods promises to reinforce the efficacy and fostering of MBRs, ensuring their pivotal role in the future of sustainable wastewater administration.

Membrane bioreactors (MBRs) represent a significant innovation in the basics field of wastewater therapy, incorporating organic procedures with innovative membrane layer purification to improve effluent high quality.Membrane layer bioreactors (MBRs) combine biological therapy processes with membrane filtration to properly deal with wastewater.The combination of biological therapy with membrane layer purification in MBR systems offers countless benefits that Our site set it apart from standard wastewater therapy methods. Membrane bioreactors (MBRs) exhibit this change by incorporating biological treatment processes with membrane purification, resulting in high-grade effluent ideal for reuse.Membrane layer bioreactors (MBRs) stand for a transformative method to wastewater treatment, incorporating organic procedures with innovative membrane innovation.

Report this page